State-Of-The-Art Equipment

With over 250 CNC Machining Centers and over 400,00 square feet of manufacturing space globally, Sussek Machine Company offers state-of-the-art precision machining and assemblies. Specialized machining capabilities include but are not limited to 5-axis mill machining, pallet pool milling lines, Swiss turning, up to 7-axis CNC turning, 5-axis CNC-Hobbing, Induction heat treating, CNC balancing, broaching, and a 5-stage part washing. Custom engineered hydraulic, pneumatic, manual part holding, and assembly machines built in-house. Being an engineering driven organization with technically proficient machinist allows the company to optimize its manufacturing efficiencies and global cost structures for its customers. Sussek can design and manufacture components that are specialized for its clients’ product needs within its different facilities where each possesses a specialized focus and talent. The companies’ facilities share central resources and technology and leverage best practices across the company, with the ability to move work between facilities where necessary or prudent.

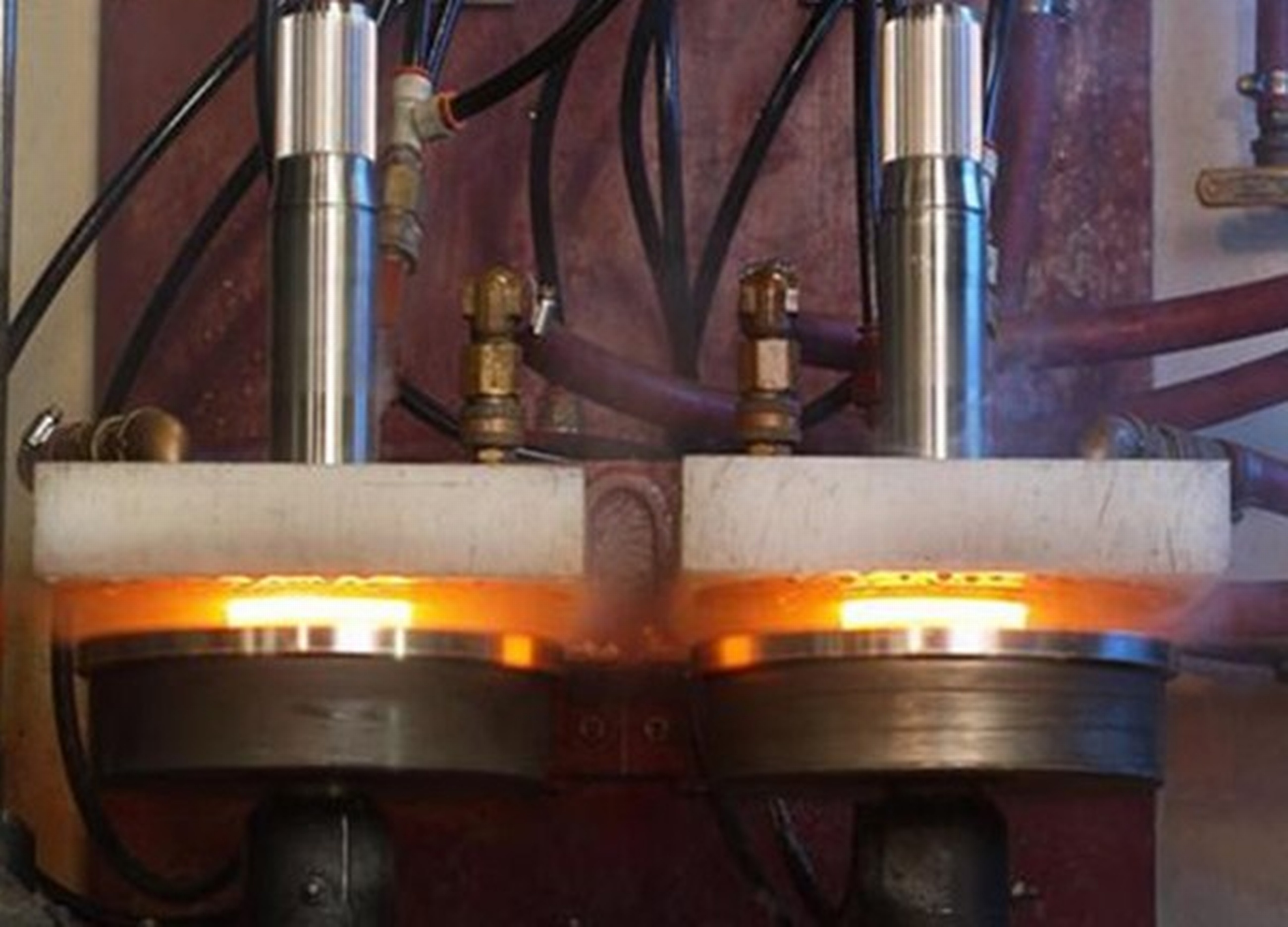

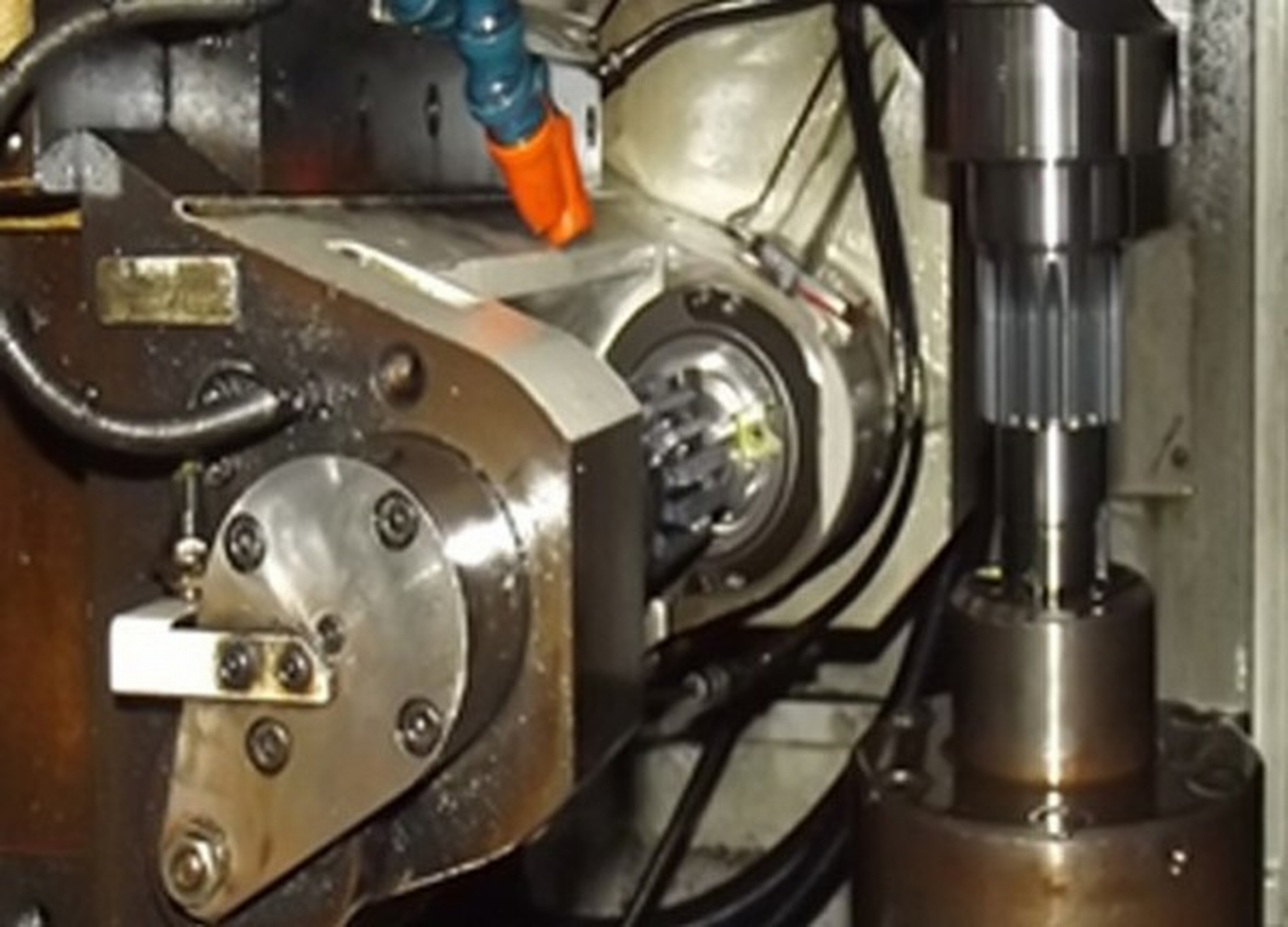

Some of our specialized machining capabilities include but are not limited to 5-axis Palletech line, 4-axis linear pallet line, 5-axis CNC-Hobbing, Radyne Induction Heat Treating, Balancing, Broaching, and a 5-stage part washing.

- Our milling machines are capable of running a part that is 41"x 35" x 38" with a part and fixture weight of 3300lbs.

- Our hob is capable of running parts that are 9" diameter and have a height of 16".

- Our lathe machines are capable of running a part with a diameter of 28", a height of 29", and a load capacity of 1433lbs.

- The CNC grinder operation is capable of running a part with an 11" diameter and load weight of 330lbs.

- The heat treat operation is capable of handling a part with a height of 60" and weighing up to 250lbs.

In addition to our machining capabilities we offer customizable packaging, hydraulic, electric, and pneumatic assembly to meet our customer's needs. We also have an internal automation team that works to automate our cells for increased production and quality.

Sussek Machine is willing to invest in dedicated manufacturing cells for high volume parts, automation when justified or add new machining capabilities to ensure customers demand is exceeded with quality products that are delivered on-time.

Equipment List

| MACHINE | QUANTITY | DESCRIPTION | MAX TRAVEL | ACCESSORY |

|---|---|---|---|---|

| Horizontal Machine Centers | 17 | 4-Axis Mills | 1050 X 900 X 980 | Many with High Pressure Coolant, up to 240 tools. |

| Vertical Machining Centers | 95 | Up to full 5-Axis | 1400 X 600 X 675 | Many with High Pressure Coolant, up to 60 tools. |

| Horizontal Turning Centers | 2 | Mill & Lathe | X: 335 / Z: 1110 | 90° & 0° Live Holders, 12" chuck |

| Single Spindle Horizontal Lathe | 84 | Up to 4-axis | X: 400 / Z: 820 | Up to 15" chucks, Programmable tail stock |

| Twin Spindle Horizontal Lathe | 1 | 2 Axis Lathe | X: 250 / Z: 265 | 12" Chucks, Parts Loader |

| Vertical Lathe | 14 | 2 Axis Lathe | X: 439.4 / Z: 800 | 18" Chuck, Live Tooling, High pressure coolant, Hi-Low Chuck pressure, Coolant Chillers |

| Horizontal Lathe With Sub-Spindle | 10 | Up to 6-Axis | X: 175.26 / Z: 508 Y: 105.00 | 8" CHUCK, 20HP, 6,000 RPM, 5HP 6,000 RPM Live Tooling, Bar Feeders, High Pressure Coolant, Tool Load Moonitoring, Parts Catcher |

| Swiss Type Screw Machine Lathe | 10 | Up To 7-Axis | Ø32.0 X 320 | Ø32.0 Max With Bar Feeders, High Pressure Coolant, Up To 35 Tools. |

| Balancer | 4 | Single Plane | Up To 165 lbs | Auto Correction, Ø24.0" Max, 11.0" Max Drill Radius, Hydraulic Drill Supports |

| Horizontal Broacher | 3 | Horizontal | Ø508 X 1524 | 20,000 # Pull |

| Double Ram Vertical Broacher | 1 | Double Ram Vertical | Ø304.8 X 1422.4 | Ø241.3 Max If Doing Two Parts At Time |

| Induction Heat Treater | 1 | 25 kHz | Ø304.8 X 762 | 150# Total, 8" Spindle Centers |

| Induction Heat Treater | 1 | 3 /10 kHz | Ø304.8 X 1524 | 250# Per spindle, 12" Spindle Centers |

| CNC OD Grinder | 1 | Angle Head | Ø400 X 1047.75 | |

| CNC OD Grinder | 1 | Plain Cylinder | Ø300 X 508 | |

| Surface Grinder | 8 | Face Grind | 440 x 1100 | Magnetic Table, 3-AXIS |

| Cutoff / Band Saw | 6 | Saw | Ø280 X 580 | Bar Feeder, Band Speed 10-120 M/Min |

| Knee Mill | 4 | MILL | 880 X 395 X 380 | |

| Engine Lathe | 5 | LATHE | 500 X 2032 | |

| Engine Lathe | 4 | Lathe | ||

| CNC Hob | 1 | 5-Axis | Ø226 X 249 | 4.23 Max DP |

| CMM | 10 | CMM | 1200 X 3000 X 1000 | PC-DMIS |

| Welder | 1 | MIG WELDER | Welding Power Source | |

| Welder | 1 | TIG WELDER | Welding Power Source, AC-DC Gas Tungsten Arc | |

| Welder | 1 | PLASMA CUTTER | 125PSI / 65PSI, 300 SCFH | |

| Welder | 1 | MIG WELDER | 200 AMPS AT 28 VDC, 60% DUTY CYCLE. 250 AMPS AT 28VDC, 40% DUTY CYCLE | |

| Robot | 7 | Six-Axis Robot | IR Vision-2D | |

| Jig Grinder | 1 | 610 X 914.4 | ||

| Lapping Machine | 1 | Ø508.0 | ||

| Barrel Finisher | 1 | Ø10.25 x 17.25 | 10HP 4.7cu ft | |

| Plasma Cutter | 1 | 22.0MM |